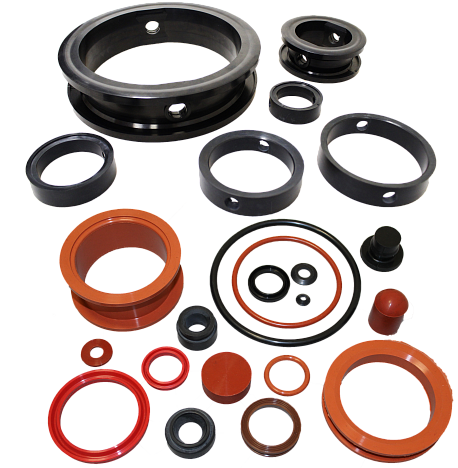

BV-TNG Elastic mechanical seal

DIN 24960

Analog:

Sterling GNZ, Burgmann HJ92N / HJ97N

Friction couple materials:

Carbographite (Рђ, Р’)

tungsten carbide (РёР·)

silicon carbide (Qi, Q2)

ceramics Al203 (V)

Secondary seals:

fluorine rubber, FKM (V)

nitrile rubber (Р )

ethylene-propylene rubber, EPDM (Р•)

EFKM, FFKM(for example KalrezВ®)

fluorine rubber in PTFE shell, FEP

Parameters:

СЂ = 40 bars

t = -50 ... 220°С

v = 20m/s

Designed with a central protected spring

The location of the spring prevents any contact with the fluid being pumped

Ideal for viscous media, liquids containing abrasive particles and so on,

If it is to be used in sterile processes, it is supplied with electropolished surfaces and profiled elastomer rings to prevent cavity formation

Hydraulically relieved

Does not depend on the direction of shaft rotation

Dimensions as per DIN 24960 (EN12756)

|

d |

d3 |

D6 |

D7 |

L1k |

L2 |

L3 |

|

14 |

24.0 |

21 |

25 |

38.0 |

5.5 |

32.5 |

|

16 |

26.0 |

23 |

27 |

40.0 |

5.5 |

34.5 |

|

18 |

32.0 |

27 |

33 |

37.5 |

7.0 |

30.5 |

|

20 |

34.0 |

29 |

35 |

37.5 |

7.0 |

30.5 |

|

24 |

38.0 |

33 |

39 |

40.0 |

7.0 |

33.0 |

|

25 |

39.0 |

34 |

40 |

40.0 |

7.0 |

33.0 |

|

28 |

42.0 |

37 |

43 |

42.5 |

7.0 |

35.5 |

|

30 |

44.0 |

39 |

45 |

42.5 |

7.0 |

35.5 |

|

32 |

47.0 |

42 |

48 |

42.5 |

7.0 |

35.5 |

|

33 |

47.0 |

42 |

48 |

42.5 |

7.0 |

35.5 |

|

35 |

49.0 |

44 |

50 |

42.5 |

7.0 |

35.5 |

|

38 |

54.0 |

49 |

56 |

45.0 |

8.0 |

37.0 |

|

40 |

56.0 |

51 |

58 |

45.0 |

8.0 |

37.0 |

|

43 |

59.0 |

54 |

61 |

45.0 |

8.0 |

37.0 |

|

44 |

61.0 |

56 |

63 |

45.0 |

8.0 |

37.0 |

|

50 |

66.0 |

62 |

70 |

47.5 |

9.5 |

38.0 |

|

53 |

68.5 |

65 |

73 |

47.5 |

9.5 |

38.0 |

|

60 |

80.0 |

72 |

80 |

52.5 |

10.5 |

42.0 |

|

65 |

85.0 |

77 |

85 |

52.5 |

10.5 |

42.0 |

|

70 |

90.0 |

83 |

92 |

60.0 |

11.5 |

48.5 |

|

75 |

99.0 |

88 |

97 |

60.0 |

11.5 |

48.5 |

|

80 |

104.0 |

95 |

105 |

60.0 |

11.5 |

48.5 |

|

95 |

119.0 |

110 |

120 |

65.0 |

13.0 |

52.0 |

|

100 |

124.0 |

115 |

125 |

65.0 |

13.0 |

52.0 |

- Description

DIN 24960

Analog:

Sterling GNZ, Burgmann HJ92N / HJ97N

Friction couple materials:

Carbographite (Рђ, Р’)

tungsten carbide (РёР·)

silicon carbide (Qi, Q2)

ceramics Al203 (V)

Secondary seals:

fluorine rubber, FKM (V)

nitrile rubber (Р )

ethylene-propylene rubber, EPDM (Р•)

EFKM, FFKM(for example KalrezВ®)

fluorine rubber in PTFE shell, FEP

Parameters:

СЂ = 40 bars

t = -50 ... 220°С

v = 20m/s

Designed with a central protected spring

The location of the spring prevents any contact with the fluid being pumped

Ideal for viscous media, liquids containing abrasive particles and so on,

If it is to be used in sterile processes, it is supplied with electropolished surfaces and profiled elastomer rings to prevent cavity formation

Hydraulically relieved

Does not depend on the direction of shaft rotation

Dimensions as per DIN 24960 (EN12756)

d

d3

D6

D7

L1k

L2

L3

14

24.0

21

25

38.0

5.5

32.5

16

26.0

23

27

40.0

5.5

34.5

18

32.0

27

33

37.5

7.0

30.5

20

34.0

29

35

37.5

7.0

30.5

24

38.0

33

39

40.0

7.0

33.0

25

39.0

34

40

40.0

7.0

33.0

28

42.0

37

43

42.5

7.0

35.5

30

44.0

39

45

42.5

7.0

35.5

32

47.0

42

48

42.5

7.0

35.5

33

47.0

42

48

42.5

7.0

35.5

35

49.0

44

50

42.5

7.0

35.5

38

54.0

49

56

45.0

8.0

37.0

40

56.0

51

58

45.0

8.0

37.0

43

59.0

54

61

45.0

8.0

37.0

44

61.0

56

63

45.0

8.0

37.0

50

66.0

62

70

47.5

9.5

38.0

53

68.5

65

73

47.5

9.5

38.0

60

80.0

72

80

52.5

10.5

42.0

65

85.0

77

85

52.5

10.5

42.0

70

90.0

83

92

60.0

11.5

48.5

75

99.0

88

97

60.0

11.5

48.5

80

104.0

95

105

60.0

11.5

48.5

95

119.0

110

120

65.0

13.0

52.0

100

124.0

115

125

65.0

13.0

52.0

- Name

- BV-TNG Elastic mechanical seal

en

en

Русский [ru]

Русский [ru]