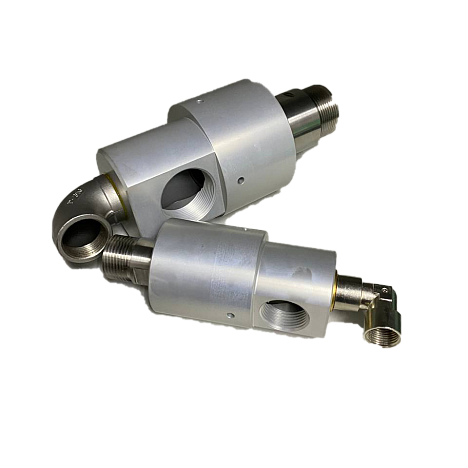

Cartridge seals

On average, only 10% of mechanical seals will last for their entire service life. The remaining 90% will fail prematurely, mostly due to improper operation, assembly or selection. Much better operating characteristics can be achieved by using cartridge seals. A cartridge seal is a compact unit ensuring its easy replacement and preventing mistakes during assembly. This type of design allows considerable axial shifts, whereas its hydraulic relief makes it possible to use it at high operating pressures.

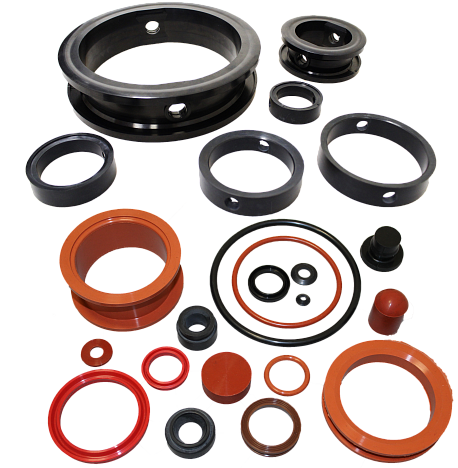

Design:

- the springs are installed in the mating part of the seal, which allows high rotation speeds;

- the dynamically loaded secondary seals are installed in the 'atmospheric' part of the seal, which prevents blocking their operation due to working liquid sediments;

- the dynamically loaded secondary seals do not contact the shaft sleeve and, therefore, do not influence the sleeve alignment in relation to the shaft;

- the compact design of the sealing surfaces ensures optimal torque transfer even at maximum allowable angle and axial shaft deviations;

- the design of the multi-spring seals ensures even load distribution on the sealing surface;

- the springs are not subjected to permanent dynamic load and do not contact the working liquid, which prevents their blocking and ensures reliable operation.

The double hydraulic relief makes the seal reliable, ensures its unencumbered operation even in case of sharp pressure fluctuations, and completely prevents the seal from failing unexpectedly.

![]() Manual for operation of mechanical seals UCA, UCB, UCC, UCD 1.42 MB

Manual for operation of mechanical seals UCA, UCB, UCC, UCD 1.42 MB

![]() Cartridge seals UCA, UCB 214.03 kB

Cartridge seals UCA, UCB 214.03 kB

![]() Cartridge seals UCC, UCD 217.08 kB

Cartridge seals UCC, UCD 217.08 kB

en

en

Русский [ru]

Русский [ru]