The AvtokomTehnolodgy group of companies has been operating since 2008 and has successfully established itself in the market among manufacturers and suppliers of components for industrial equipment in the oil and gas, food, metallurgical and other sectors of the economy.

The AvtokomTehnolodgy group of companies successfully cooperates with many enterprises and holdings in Russia and abroad.

The goal of our company is the development of production technologies from “idea to implementation”. And in order to achieve this goal, in 2019 the management of the Company decided to implement several large projects whose tasks are to increase the scientific potential of the Company and production capacities.

So, the first step of the AvtokomTehnolodgy group of companies was cooperation with the Department of Science and Research of Volgograd State Technical University, which allows you to introduce the latest technologies and solve complex technical problems, from selecting recipes for the production of product materials to developing design and engineering solutions for manufacturing products at the request of the Customer.

To increase production capacities, as well as supporting the state program of import substitution, the management of the AvtokomTehnolodgy group of companies developed a project to increase the production of import-substituting types of rubber products for the oil refining and food industries. With this idea, the AvtokomTehnolodgy group of companies in 2019 filed an application to participate in the federal industrial development program of the Volgograd Region. The idea of the AvtokomTehnolodgy group of companies was recognized as promising and received the support of the Volgograd Region Federal Industry Development Fund. Participation in the program allowed the AvtokomTehnolodgy group of companies to begin a major project to modernize production, which takes place in several stages, and includes the construction of new workshop facilities and the purchase of new modern equipment.

Currently, for the implementation of this project, the Company has purchased equipment that allows the production of industrial products, namely components for the Russian market and exports to the CIS countries, which are in no way inferior in quality to imported products:

- CNC milling center;

- CNC lathe;

- CNC EDM machine;

- universal screw cutting machine;

- universal screw-cutting lathe for large diameter workpieces;

- universal milling machine;

- surface grinding machine;

- circular grinding machine;

- hydraulic curing press;

- extruder syringe machine;

- milling machines;

- radial drilling machine;

- thermal furnaces for hardening and tempering of metal;

- blank band saw.

The implementation of these projects allowed the AvtokomTehnolodgy group of companies to quickly expand its product line, become more mobile and reorient production to market needs in the direction of import substitution.

We list the main activities of the company.

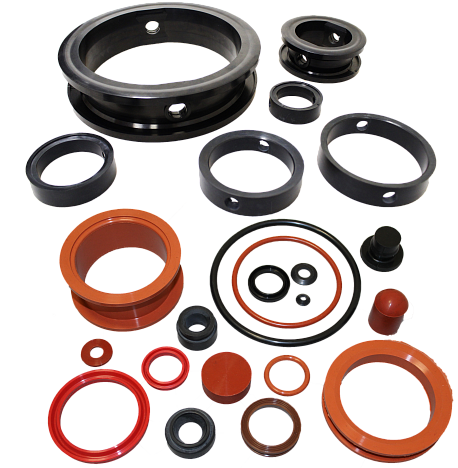

The AvtokomTehnolodgy group of companies today manufactures and supplies various types of rubber products from various materials, as well as plastic and metal products with various types of processing according to the presented sketches, samples and drawings. The AvtokomTehnolodgy group of companies successfully mastered the production of such products as cuffs for packers made of hydrogenated rubber, sealing disk taps, sealing rings and many other items demanded by the oil and gas sector and the food industry.

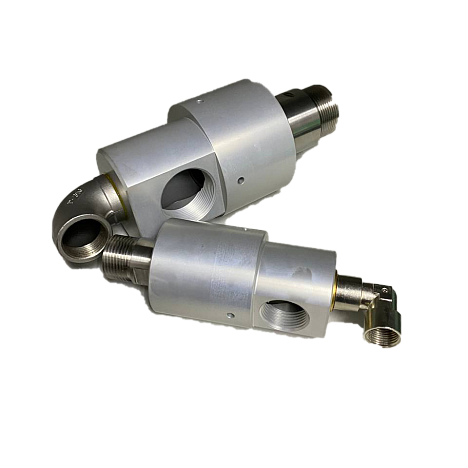

The AvtokomTehnolodgy group of companies carries out metalworking of various degrees of complexity, including:

- metal turning (flanges, rings, transitions, shafts, nuts, bushings);

- milling (processing of flat surfaces, gears, pinion shafts, gears, threaded and screw surfaces, body parts, welding and assembly products, splined shafts and bushings, keyways and other grooves, manufacture of rubber vulcanization molds);

- grinding (planes, conical and cylindrical parts, holes, shafts, bushings, grooves, fasteners);

- electroerosive processing (manufacturing complex parts of small size with high accuracy of edges, for resizing metal products, obtaining holes of various shapes, shaped cavities, profile grooves and grooves in parts made of hard alloys);

- we provide services for the design and manufacture of molds for both direct pressing of rubber goods and chamber-type molds for casting rubber goods.

The tool shop is equipped with modern high-precision equipment and has a closed mold manufacturing cycle. To prepare a commercial proposal, we need a drawing, a 3D model or a new product sample, the required amount per month.

The company works according to the drawings of the customer, and also has the technical ability to develop drawings according to the model of the part provided by the Customer.

The products manufactured by the AvtokomTehnolodgy group of companies are manufactured using modern technologies from domestic raw materials and materials, the presence of the laboratory allows for incoming quality control of raw materials and materials used in production, as well as continuous quality control of products.

The laboratory is fully equipped with new modern equipment, including a tensile testing machine with a PC graph, a rotorless rheometer, an analytical balance, a drying oven, a stationary and portable hardness tester (electronic and mechanical), a fume hood for testing rubber in various environments, allowing determine all the parameters of rubber compounds and their vulcanizates.

Laboratory equipment allows specialists of the AvtokomTehnolodgy group of companies to deal with:

- development of rubber compounds formulations with a set of properties specified by the customer, to refine the parameters of technological processes for the production of rubber products;

- determine the change in the properties of rubbers under the influence of many aggressive factors, predicting the performance of the products under operating conditions (static loads, dynamic loads, resistance to thermal aging, resistance to liquid and gaseous aggressive environments, determination of frost resistance, etc.);

- carry out full control of all chemicals and semi-finished products entering production.

We offer you: competitive prices, exact adherence to order dates, high quality, compliance with all technical requirements.

The AvtokomTehnolodgy group of companies is aimed at long-term cooperation with its customers, offering effective engineering solutions.

en

en

Русский [ru]

Русский [ru]