NV-1 Mechanical seal with set of small springs

DIN 24960

Disadvantages of the central spring design: uneven load distribution along the friction belt in the couple due to the non-perpendicularity of the spring ends in relation to its axis, resulting in the couple being subject to unilateral wear, a comparatively large size of the spring in the axial direction and its inefficiency for large-sized shafts.

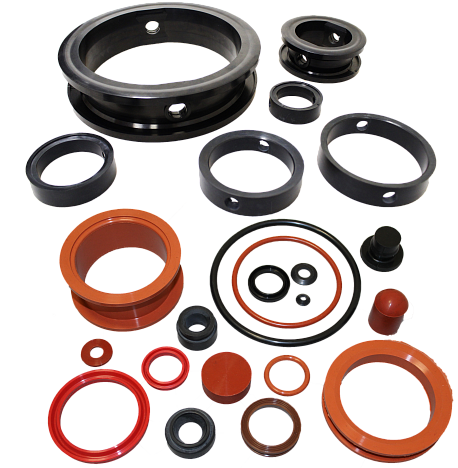

Mechanical seals with a set of small cylindrical springs have a smaller axial size than central spring seals and have no limitations as to the shaft diameter. By using a set of small springs, it is possible to increase unification of the Mechanical seal design: one and the same spring can be used for sealing different diameters. The sealing force can be adjusted by changing the number of springs and keeping constant the axial movement of the rigid element. The seal design ensures its low-cost maintenance due to easily replaceable parts. This kind of seal is often used in pumps at refineries, petrochemical plants and in the process industry. The secondary seal on the axis is completed by means of an O-ring or PTFE ring wedgewise.

The disadvantage of this kind of rigid elements is the small diameter (1 mm) of the spring wire, which makes its application in corrosive media limited.

The rigid element design based on a set of small springs is not recommended for use in media with solid inclusions.

The springs are quickly clogged with solid inclusions, which causes the rigid element to lose its axial movement ability.

The more compact version allows it to be used in pumps for heating, in sludge and fecal pumps, as well as in food industry pumps.

Analog:

AESSEAL M03 / M03S, Burgmann BT-C56.KU / BT-C5.KU / M74N, John Crane 59U / 58U, Vulcan 1659 / 1659S, Sterling 259 / 259S, Type 153 / 251 by OST

Materials for sealing faces:

carbographite

chromium steel

nickel chrome steel

increased rigidity nickel chrome steel

tungsten carbide

silicon carbide

ceramics (AI2O3)

Operating limits:

p = 16 bars

t = -40 ... 220В°C

v = 20 m/s

NV-1.1 carbographite pressed into the sealing surface frame

NV-1.2 silicon carbide pressed into the sealing surface frame

NV-1.3 seal surface with tungsten carbide soldered on

|

d1 |

d3 |

D4 |

D6 |

D7 |

D8 |

l3 |

l4 |

l1k |

|

18 |

32 |

34 |

27 |

33 |

3 |

26 |

11.5 |

37.5 |

|

20 |

34 |

36 |

29 |

35 |

3 |

26 |

11.5 |

37.5 |

|

22 |

36 |

38 |

31 |

37 |

3 |

26 |

11.5 |

37.5 |

|

24 |

38 |

40 |

33 |

39 |

3 |

28.5 |

11.5 |

40 |

|

25 |

39 |

41 |

34 |

40 |

3 |

28.5 |

11.5 |

40 |

|

28 |

42 |

44 |

37 |

43 |

3 |

31 |

11.5 |

42.5 |

|

30 |

44 |

46 |

39 |

45 |

3 |

31 |

11.5 |

42.5 |

|

32 |

46 |

48 |

42 |

48 |

3 |

31 |

11.5 |

42.5 |

|

33 |

47 |

49 |

42 |

48 |

3 |

31 |

11.5 |

42.5 |

|

35 |

49 |

51 |

44 |

50 |

3 |

31 |

11.5 |

42.5 |

|

38 |

54 |

58 |

49 |

56 |

4 |

31 |

14 |

45 |

|

40 |

56 |

60 |

51 |

58 |

4 |

31 |

14 |

45 |

|

43 |

59 |

63 |

54 |

61 |

4 |

31 |

14 |

45 |

|

45 |

61 |

65 |

56 |

63 |

4 |

31 |

14 |

45 |

|

48 |

64 |

68 |

59 |

66 |

4 |

31 |

14 |

45 |

|

50 |

66 |

70 |

62 |

70 |

4 |

32.5 |

15 |

47.5 |

|

53 |

69 |

73 |

65 |

73 |

4 |

32.5 |

15 |

47.5 |

|

55 |

71 |

75 |

67 |

75 |

4 |

32.5 |

15 |

47.5 |

|

58 |

78 |

83 |

70 |

78 |

4 |

37.5 |

15 |

52.5 |

|

60 |

80 |

85 |

72 |

80 |

4 |

37.5 |

15 |

52.5 |

|

63 |

83 |

88 |

75 |

83 |

4 |

37.5 |

15 |

52.5 |

|

65 |

85 |

90 |

77 |

85 |

4 |

37.5 |

15 |

52.5 |

|

68 |

88 |

93 |

81 |

90 |

4 |

37.5 |

15 |

52.5 |

|

70 |

90 |

95 |

83 |

92 |

4 |

43 |

17 |

60 |

|

75 |

99 |

104 |

88 |

97 |

4 |

43 |

17 |

60 |

|

80 |

104 |

109 |

95 |

105 |

4 |

43 |

17 |

60 |

|

85 |

109 |

114 |

100 |

110 |

4 |

43 |

17 |

60 |

|

90 |

114 |

119 |

105 |

115 |

4 |

48 |

17 |

65 |

|

95 |

119 |

124 |

110 |

120 |

4 |

48 |

17 |

65 |

|

100 |

124 |

129 |

115 |

125 |

4 |

48 |

17 |

65 |

+ customized seals as per your drawings and specifications

- Description

DIN 24960

Disadvantages of the central spring design: uneven load distribution along the friction belt in the couple due to the non-perpendicularity of the spring ends in relation to its axis, resulting in the couple being subject to unilateral wear, a comparatively large size of the spring in the axial direction and its inefficiency for large-sized shafts.

Mechanical seals with a set of small cylindrical springs have a smaller axial size than central spring seals and have no limitations as to the shaft diameter. By using a set of small springs, it is possible to increase unification of the Mechanical seal design: one and the same spring can be used for sealing different diameters. The sealing force can be adjusted by changing the number of springs and keeping constant the axial movement of the rigid element. The seal design ensures its low-cost maintenance due to easily replaceable parts. This kind of seal is often used in pumps at refineries, petrochemical plants and in the process industry. The secondary seal on the axis is completed by means of an O-ring or PTFE ring wedgewise.

The disadvantage of this kind of rigid elements is the small diameter (1 mm) of the spring wire, which makes its application in corrosive media limited.

The rigid element design based on a set of small springs is not recommended for use in media with solid inclusions.

The springs are quickly clogged with solid inclusions, which causes the rigid element to lose its axial movement ability.The more compact version allows it to be used in pumps for heating, in sludge and fecal pumps, as well as in food industry pumps.

Analog:

AESSEAL M03 / M03S, Burgmann BT-C56.KU / BT-C5.KU / M74N, John Crane 59U / 58U, Vulcan 1659 / 1659S, Sterling 259 / 259S, Type 153 / 251 by OST

Materials for sealing faces:

carbographite

chromium steel

nickel chrome steel

increased rigidity nickel chrome steel

tungsten carbide

silicon carbide

ceramics (AI2O3)

Operating limits:

p = 16 bars

t = -40 ... 220В°C

v = 20 m/s

NV-1.1 carbographite pressed into the sealing surface frame

NV-1.2 silicon carbide pressed into the sealing surface frame

NV-1.3 seal surface with tungsten carbide soldered on

d1

d3

D4

D6

D7

D8

l3

l4

l1k

18

32

34

27

33

3

26

11.5

37.5

20

34

36

29

35

3

26

11.5

37.5

22

36

38

31

37

3

26

11.5

37.5

24

38

40

33

39

3

28.5

11.5

40

25

39

41

34

40

3

28.5

11.5

40

28

42

44

37

43

3

31

11.5

42.5

30

44

46

39

45

3

31

11.5

42.5

32

46

48

42

48

3

31

11.5

42.5

33

47

49

42

48

3

31

11.5

42.5

35

49

51

44

50

3

31

11.5

42.5

38

54

58

49

56

4

31

14

45

40

56

60

51

58

4

31

14

45

43

59

63

54

61

4

31

14

45

45

61

65

56

63

4

31

14

45

48

64

68

59

66

4

31

14

45

50

66

70

62

70

4

32.5

15

47.5

53

69

73

65

73

4

32.5

15

47.5

55

71

75

67

75

4

32.5

15

47.5

58

78

83

70

78

4

37.5

15

52.5

60

80

85

72

80

4

37.5

15

52.5

63

83

88

75

83

4

37.5

15

52.5

65

85

90

77

85

4

37.5

15

52.5

68

88

93

81

90

4

37.5

15

52.5

70

90

95

83

92

4

43

17

60

75

99

104

88

97

4

43

17

60

80

104

109

95

105

4

43

17

60

85

109

114

100

110

4

43

17

60

90

114

119

105

115

4

48

17

65

95

119

124

110

120

4

48

17

65

100

124

129

115

125

4

48

17

65

+ customized seals as per your drawings and specifications

- Name

- NV-1 Mechanical seal with set of small springs

en

en

Русский [ru]

Русский [ru]