HP-TPD

Description:

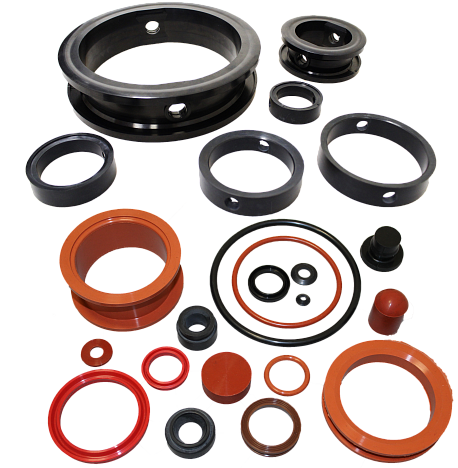

The TPD cuff consists of two rings. The dynamic part is a ring of a certain shape made of PTFE material filled with bronze, and the O-ring, which plays the role of an activator, is a static part.

Technical specifications:

Pressure: < 600 bar.

Speed: < 15 m/s.

Temperature: from -30В°C to +100В°C (for a standard O-ring made of NBR material) with a short-term peak value of up to +120В°C. For a different temperature range, the O-ring material should be replaced by a more suitable.

Material:

PTFE material filled with bronze - for standard type; NBR material for O-ring.

Material code: TN.

Installation:

During installation, it is necessary to observe the allowable value of the roughness of the piston surface (also grinding the landing groove).

Mount the cuff for the lip of the landing groove until the piston moves lightly. The seal must always be lubricated before installation.

(For more information, see the Installation Instructions on page 1.2.14).

- Description

Description:

The TPD cuff consists of two rings. The dynamic part is a ring of a certain shape made of PTFE material filled with bronze, and the O-ring, which plays the role of an activator, is a static part.

Technical specifications:

Pressure: < 600 bar.

Speed: < 15 m/s.

Temperature: from -30В°C to +100В°C (for a standard O-ring made of NBR material) with a short-term peak value of up to +120В°C. For a different temperature range, the O-ring material should be replaced by a more suitable.

Material:

PTFE material filled with bronze - for standard type; NBR material for O-ring.

Material code: TN.

Installation:

During installation, it is necessary to observe the allowable value of the roughness of the piston surface (also grinding the landing groove).

Mount the cuff for the lip of the landing groove until the piston moves lightly. The seal must always be lubricated before installation.

(For more information, see the Installation Instructions on page 1.2.14).

en

en

Русский [ru]

Русский [ru]