HG-WAT

Description:

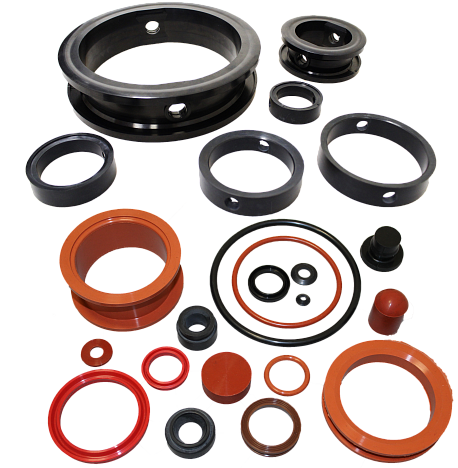

Thanks to its special profile and design, the WAT wiper ring can be self-aligned when the stem is displaced during operation. The cuff has two edges: an edge closer to the stem, longer, very flexible and movable; The edge of the static part is shorter and prevents contamination from coming into contact with the locking protrusion.

Technical specifications:

Speed: < 1 m/s.

Temperature: from -35В°C to +100В°C with a peak value of +110В°C.

Operating environment: water at room temperature, mineral oils (see Table 1 on page 1.2.4).

Material:

Material: polyurethane type ""C0"", with high modulus of elasticity, low permanent deformation and high abrasion resistance.

Standard polyurethane 90 Shore A (B0) in diameter up to 35 mm.

Hardness: Shore 93 A 2.

It is also possible to use more rigid types of polyurethane for a highly contaminated working environment.

Material code: C0.

Installation:

Installation is more convenient, since it is carried out in a semi-open groove.

It is recommended that the permissible surface roughness is observed (grind the surface of the landing groove).

(For more details, see the Installation Instructions on page 1.2.14).

- Description

Description:

Thanks to its special profile and design, the WAT wiper ring can be self-aligned when the stem is displaced during operation. The cuff has two edges: an edge closer to the stem, longer, very flexible and movable; The edge of the static part is shorter and prevents contamination from coming into contact with the locking protrusion.

Technical specifications:

Speed: < 1 m/s.

Temperature: from -35В°C to +100В°C with a peak value of +110В°C.

Operating environment: water at room temperature, mineral oils (see Table 1 on page 1.2.4).

Material:

Material: polyurethane type ""C0"", with high modulus of elasticity, low permanent deformation and high abrasion resistance.

Standard polyurethane 90 Shore A (B0) in diameter up to 35 mm.

Hardness: Shore 93 A 2.

It is also possible to use more rigid types of polyurethane for a highly contaminated working environment.

Material code: C0.

Installation:

Installation is more convenient, since it is carried out in a semi-open groove.

It is recommended that the permissible surface roughness is observed (grind the surface of the landing groove).

(For more details, see the Installation Instructions on page 1.2.14).

en

en

Русский [ru]

Русский [ru]