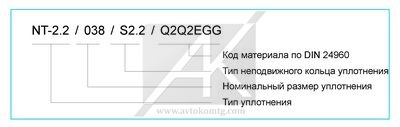

Seal marking when placing an order

Seal marking when placing an order:

Seal marking as per DIN 24960:

Seal design:

Position 1:

Version:

N=standard

К=short

С=the spring is in the stationary part

Position 2:

Design:

U=not relieved

В=relieved

С=0

Position 3, 4, 5:

Mechanical seal nominal diameter (E.g. 025 for the 25 mm shaft diameter)

Position 6:

Direction of shaft rotation:

R= right rotation - from the mating ring side, the rotating part rotates clockwise

L= left rotation - from the mating ring side, the rotating part rotates countercloskwise

S= does not depend on the direction of rotation

Position 7:

Torque transfer:

0=without pin

1=with pin

2=other

Designation of materials:

Position 8: Rotating ring

Position 9: Mating ring

Carbographites:

А=stibium impregnated carbographite

В=tar impregnated carbographite

С=other carbographhite based materials

Metals:

D=carbon steel

Е=chromium steel

F=nickel chrome steel

F1=Increased hardness nickel chrome steel(up to 64HRC)

N=bronze

Р=gray cast iron

Т=other metals

Carbides:

U1=cobalt bonded tungsten carbide

U2=nckel bonded tungsten carbde

Q1=synthesized silicon carbide

Q2=reaction sintered silicon carbide

J=other carbides

Ceramics:

V=ceramics Al2O3

Synthetic materials:

Y1=glass-filled fluoroplastic

Y2=graphte-filled fluoroplastic

Y21=carbon-filled fluoroplastic

Z=other synthetic materials

Position 10:

Secondary seal materials:

Elastomers:

В=butyl rubber

Е=ethylene propylene rubber (EPDM)

К=perfluorinated rubber (FFKM)-Kalrez

Р=nitrile rubber (NBR)-perbunan

S=silicon rubber (MVQ)

V=fluorine rubber (FPM)-Viton

М=elastomer in a fluoroplastic shell

Non-elastomers:

G=graphite (Graphoil)

Т=fluoroplastic

Position 11:

Spring materials:

G=CrNiMo steel

F1=Hastelloy C

Position 12:

Materials for other parts:

D=carbon steel

Е=chromium steel

F=nickel chrome steel

Т=other materials

G=CrNiMo steel

F1=Hastelloy C

en

en

Русский [ru]

Русский [ru]