General recommendations:

When conducting work, please observe general safety rules and requirements. Before starting mechanical seal installation work, make sure that the equipment has been stopped, is not under pressure and has been cooled. No alterations to the design or reworking of the mechanical seal is allowed.

Clean the seal chamber and inspect it for damage.

Check the installtion sizes. Check the axial and radial beat relative to the seal chamber for allowable values.

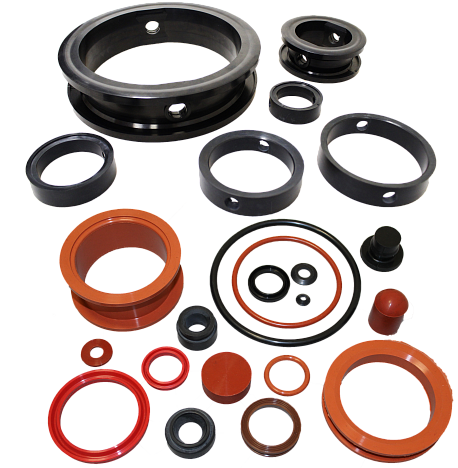

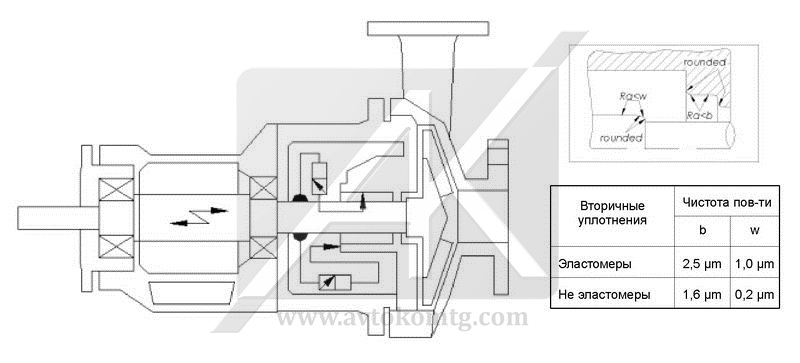

The surfaces for round section sealing rings, including all chamfers and recesses, shall have a maximum surface smoothmess (Ra) of 1.6 for static rings and 0.8 for round section dynamic rings. All mounting surfaces on which the mechanical seals are installed shall have a minimum roundness of 3 mm or a 2x30 mm chamfer (as per ISO 21049).

Do not place the friction rings on an unprotected surface with the lapped area down.

To reduce friction during elastomer installation, lubricate the mounting surfaces with suds or a silicon-based lubricant.

Do not apply the lubricant on the friction surface! Perform installation in dry and clean conditions.

Perform installation carefully. Do not use excessive force. Otherwise, the ceramic articles may be deformed or broken.

Do not allow the ethylene propylene rubber elastomers (EPR, EPDM) to contact oil products and mineral oils!

IMPORTANT:

Mechanical seals with tapered springs depend on the direction of shaft rotation. If the shaft rotates clockwise, the right winding of the spring is required (as per the direction on the drive!), and the left winding shall be used for the counterclockwise rotation. To make installation easier, install the tapered spring seal on the shaft by winding the spring in the direction coinciding with the spring winding direction.

Mechanical seals with rubber bellows are easily installed by twisting and using suds. Do not use oils and lubricants! Apply pressure only to the angle metal retainer rings. After the assembly, make sure that the angle rings and the spring are positioned properly and are not slanted.

Protect the mechanical seals fixed to the shaft by means of mounting screws from uninduced unscrewing by using a sealant, such as Loctite.

Do not squeeze the metal bellows to the point where they touch the lamels!

When installing the metal bellows seal on the shaft, apply force only to the bellows base.

Tighten the screws on the retainer sequentially (not crosswise) in a few goes, leaving an even gap as much as possible.

Protect the bellows from any damage. Damaged bellows may not be installed.

Operation:

If installed properly, the seal does not require maintenance, but it should be remembered that this unit is subject to wear and tear.

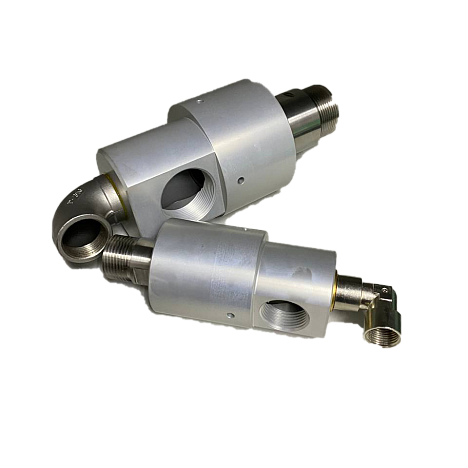

Single seals in narrow gland chambers require a supply tube to be connected from the pump delivery to remove heat and prevent sedimentation.

Remove air thoroughly before startup to avoid dry friction.

en

en

Русский [ru]

Русский [ru]